Whether it is a new car or an old car, car paint maintenance has always been a car owner friends concerned about a key project, many car friends have been inertia every year, continuous coating, crystal plating, I do not know if you know an alternative paint maintenance project has been slowly spreading within the automotive market - paint protection film.

Do you also want to put a beautiful PPF on your car? Today I will share with you the correct process of applying PPF, so that you can enhance the experience of using PPF while protecting your car!

The whole process

1. Confirmation of the construction receipt: Before applying the film, make sure the construction receipt is clearly marked with the brand, warranty time, price and other requirements, and make sure there is a paper backup.

2. Car inspection: check the whole car film there are no scratches, including paint, headlights, wheels, decorative parts, etc., to ensure that the car is intact before the film.

3. Film unboxing inspection: open the box on the spot to check the film, to ensure that the quality and type of film is consistent with the selected, to prevent theft.

4. Paste process: partners are best to be present to watch the paste process. If the time is long and can not be present to see, you can also let the shop to provide construction video, online follow-up is also possible.

5. Pick up the car: before picking up the car, be sure to check whether the wrapped edges and corners are in place, whether the car coat is flat without stains, there are no glue marks, dust spots, water stains, etc. should be carefully checked.

Tips

1. Preparation: Before applying the film, make sure the surface of the car is clean and free of dust, grease or other dirt. It is best to operate indoors or in a sheltered place to minimise the impact of external factors on the film application process.

2. Soak and cut: Put the paint protection film into water and add a small amount of cleaner or detergent to make it easier to move and adjust. Then dry the surface of the vehicle with a soft cloth.

3. Adhesion: Carefully place the film on the surface of the vehicle and adjust the position using water from a spray bottle to ensure that it matches the bodywork. At the same time, avoid contact between the film and the adhesive surface.

4. Venting: Using a special squeegee or soft squeegee, gently scrape away air bubbles from the centre of the film to the sides. This will help the film to adhere more closely to the car body.

5. Trimming: If the film does not fit tightly enough or has air bubbles in certain areas, use a heat gun or hair dryer to gently heat it up and then trim it with a squeegee.

6. Overall Inspection: After finishing the adhesion, carefully inspect the surface of the film for bubbles or wrinkles. If there are any, you can use a scraper to remove them carefully.

7. Fixing: Wait for the film to dry, then gently wipe with a soft cloth to ensure the surface is smooth, then avoid washing the car or exposing it to rainwater for the next 24 hours to ensure the film is fully fixed.

Key inspection

1. front bar: it can't be spliced, the whole film will look good when pasted.

2. Front door handle: the handle is easy to be ignored, must be neatly cut, can not appear frizzy, exposed paint.

3. Door: the car coat should be pasted into the door, otherwise it will be easy to warp and expose the paint outside.

4. Side skirts: the whole film is laminated, there can be no splicing.

5. Seams: the film must be pasted into the seams, white is not allowed.

6. Charging port: open the charging port can not be exposed to paint, the whole film is not broken.

7. Claim electronic warranty: a good film needs high quality car coat and strong craftsmanship with the construction master. Electronic warranty three code is very important to ensure that the film box code, film cylinder code, electronic warranty code is consistent, to avoid sticking to the fake film. Remember to choose the regular brand and authorised shops

Finally, there are some car coat brands have their own unique anti-counterfeiting mark, partners can also pay more attention to these anti-counterfeiting mark when choosing PPF

Confirm with the shop back to the shop review time: because the pressure-sensitive adhesive needs time to fix, so avoid washing the car and running high speed within a week. If there is a problem with the edges, return to the shop in time to check to ensure that the film effect is flawless!

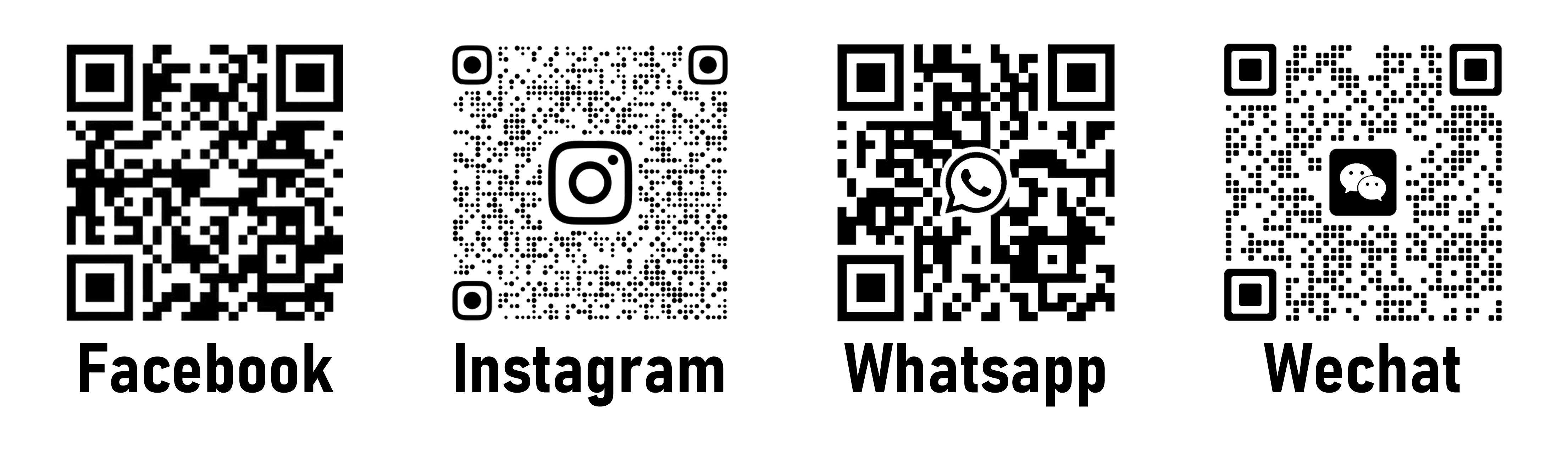

Please scan the QR code above to contact us directly.

Post time: Apr-27-2024