What is TPU Base Film?

TPU film is a film made from TPU granules through special processes such as calendering, casting, film blowing, and coating. Because TPU film has the characteristics of high moisture permeability, air permeability, cold resistance, heat resistance, wear resistance, high tension, high pulling force, and high load support, its application is very wide, and TPU film can be found in all aspects of daily life. For example, TPU films are used in packaging materials, plastic tents, water bladders, luggage composite fabrics, etc. At present, TPU films are mainly used in paint protection films in the automotive field.

From a structural point of view, TPU paint protection film is mainly composed of functional coating, TPU base film and adhesive layer. Among them, the TPU base film is the core component of PPF, and its quality is very important, and its performance requirements are extremely high.

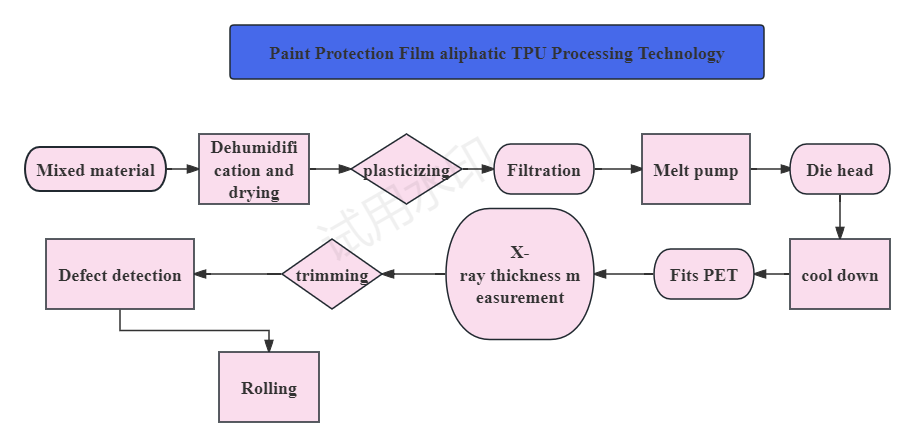

Do you know the production process of TPU?

Dehumidification and drying: molecular sieve dehumidification desiccant, more than 4h, moisture <0.01%

Process temperature: refer to the raw material manufacturers recommended, according to the hardness, MFI settings

Filtration: follow the cycle of use, to prevent black spots of foreign matter

Melt pump: extrusion volume stabilization, closed-loop control with the extruder

Screw: Select low shear structure for TPU.

Die head: design the flow channel according to the rheology of aliphatic TPU material.

Each step is critical to PPF production.

This figure briefly describes the entire process of processing aliphatic thermoplastic polyurethane from granular masterbatch to film. It involves the mixing formula of the material and the dehumidification and drying system, which heats, shears and plasticizes the solid particles into melting (melt). After filtering and measuring, the automatic die is used to shape, cool, fit the PET, and measure the thickness.

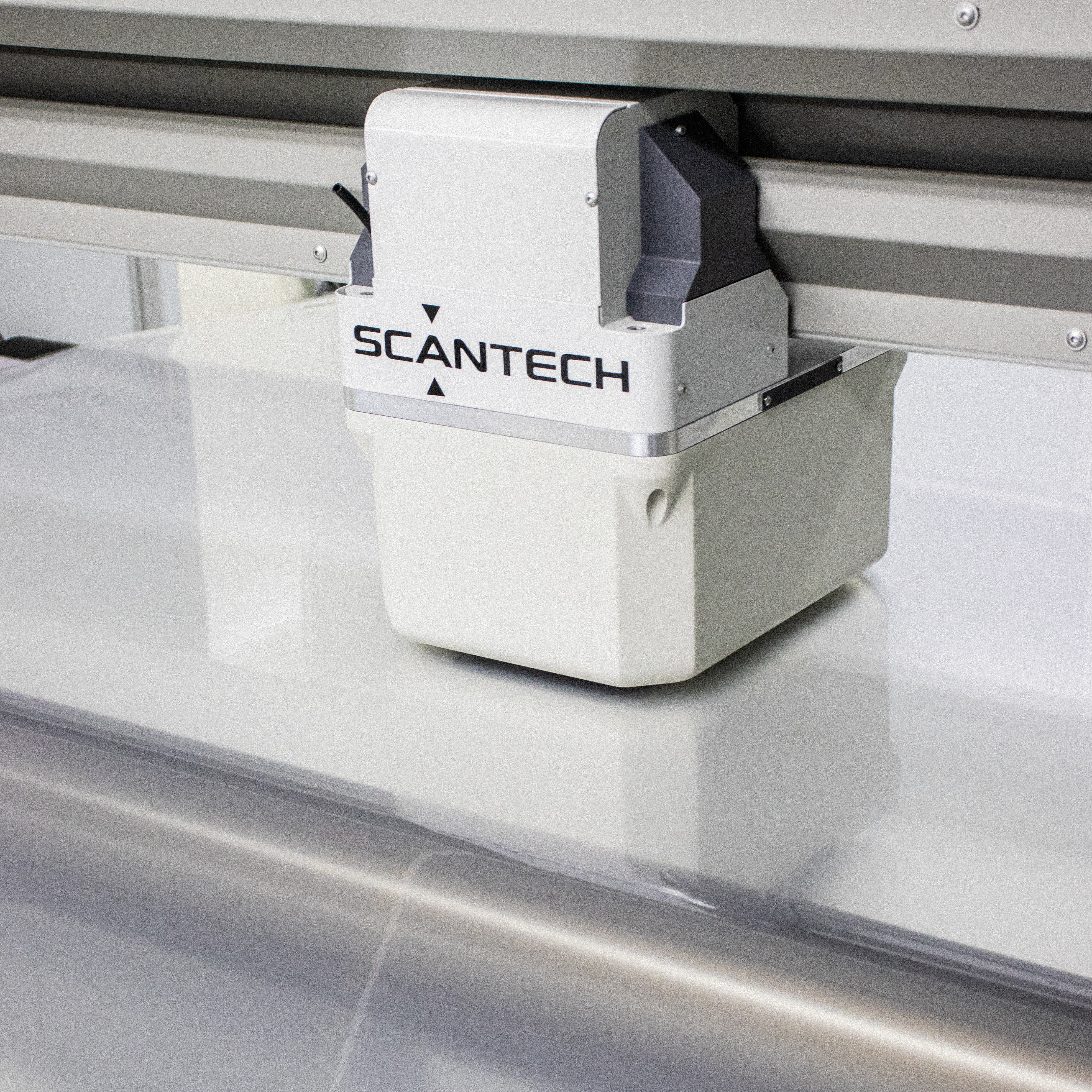

Generally, X-ray thickness measurement is used, and a confidential control system with negative feedback from the automatic die head is used. Finally, edge cutting is performed. After defect inspection, quality inspectors inspect the film from different angles to see if the physical properties meet the requirements. Finally, the rolls are rolled up and provided to customers, and there is a maturation process in between.

Processing technology points

TPU masterbatch: TPU masterbatch after high temperature

casting machine;

TPU film;

Coating machine gluing: TPU is placed on the thermosetting/light-setting coating machine and coated with a layer of acrylic glue/light-curing glue;

Laminating: Laminating the PET release film with the glued TPU;

Coating (functional layer): nano-hydrophobic coating on TPU after lamination;

Drying: drying the glue on the film with the drying process that comes with the coating machine; this process will generate a small amount of organic waste gas;

Slitting: According to the order requirements, the composite film will be slit into different sizes by the slitting machine; this process will produce edges and corners;

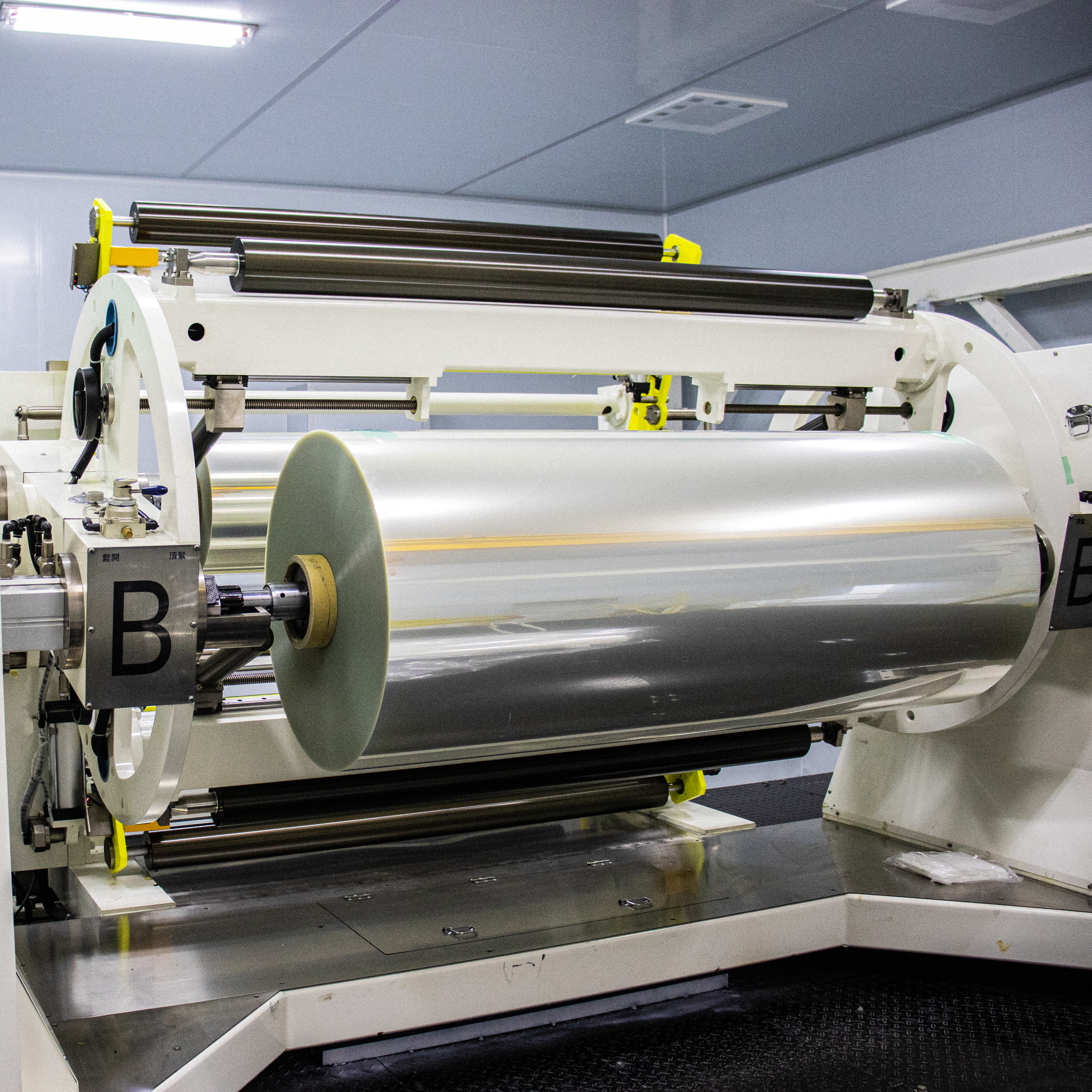

Rolling: the color change film after slitting is wound into products;

Finished product packaging: packaging the product into the warehouse.

Process diagram

TPU masterbatch

Dry

Measure thickness

Trimming

Rolling

Rolling

Roll

Please scan the QR code above to contact us directly.

Post time: Feb-23-2024