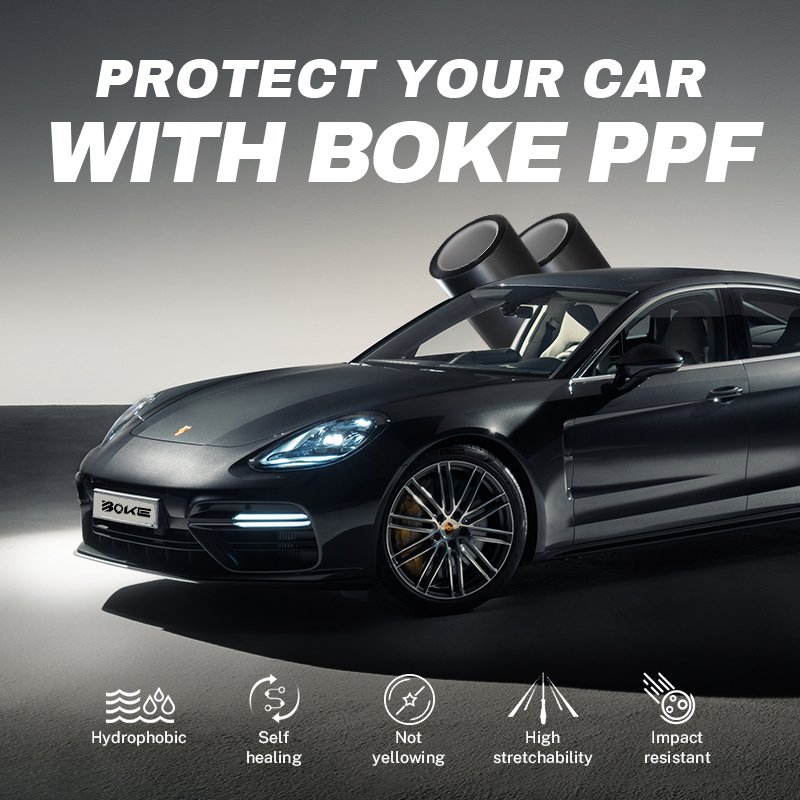

TPU-Ultimate-Black Matte Paint Protection Film

Support customization

Support customization

Own factory

Own factory

Advanced technology

Advanced technology

XTTF TPU-Ultimate-Black Matte Paint Protection Film

Advanced Self-Healing Matte Car Protection Film

Our premium offering XTTF ultimate-black matte prevents the car’s paint from fading in virtually any weather conditions while enhances car’s paintwork and gives it a premium matte finish. XTTF TPU Matte Black can offer perfect combination of longevity, durability and toughness with industry leading 5 years limited warranty, conditions apply.

Durable Performance

XTTF Paint Protection Film PPF has a strong resistance to impact and abrasion due to years of experience in creating protective films. For example, it protects vehicles from rock chips, acid rain, and minor wear, which is ideal for individuals who wish to maintain the exterior of their vehicle. XTTF TPU Matte Black meets the market's highest expectations.

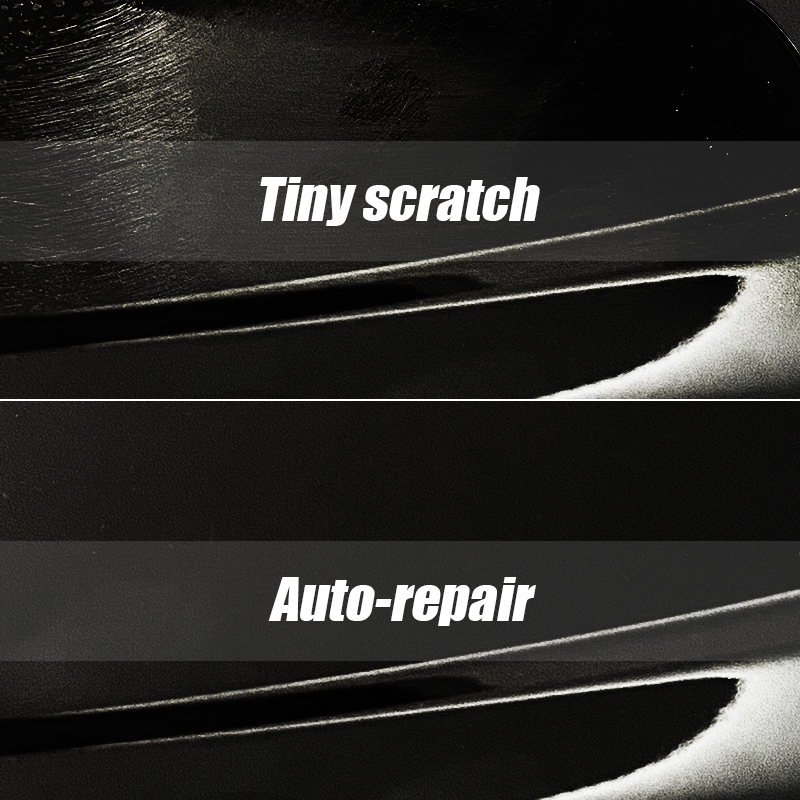

Auto-healing

Because the top layer of the PPF is an elastomeric polymer that helps preserve its natural shape, the XTTF ultimate-black matte PPF self-heals microscopic scratches and swirl marks at room temperature. XTTF PPF outperforms masking tape and irritating spray-on alternatives.

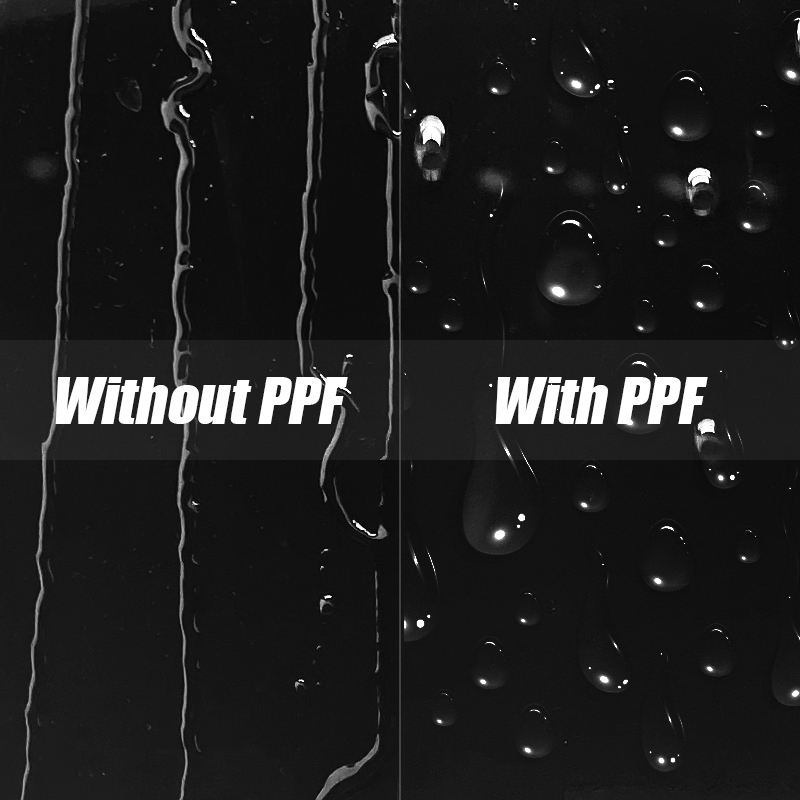

Hydrophobic Features

When it rains, the debris mixed with the water on the vehicle leaves unattractive scars. Not only does the hydrophobic quality of XTTF PPF cause rain to form large droplets with no visible watermark. Cleaning your PPF is low-maintenance because a soft cloth instead of soapy water is only needed.

The Best Film in Good Hands

Dealers and customers can clearly spot the colored ppf film base, and they can tell that the XTTF PPF has higher clarity and brightness than most other brands. The self-healing XTTF ppf film will maintain it in excellent condition. Or, give your matte paint a new appearance to protect it!

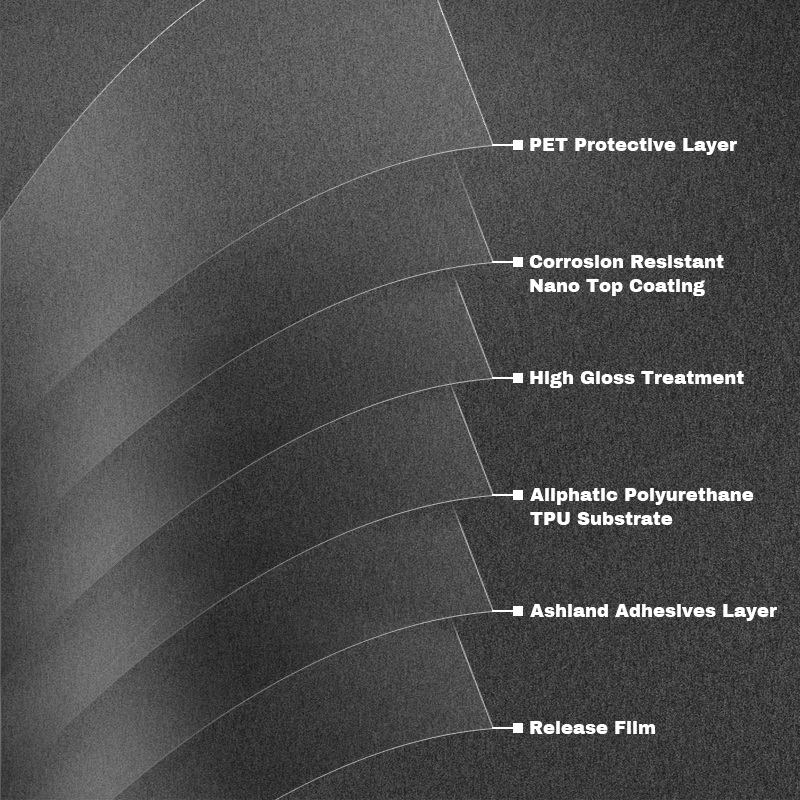

Structure Inside

1. PET Protective Layer

The functional top coating protects the coatings beneath and keeps them from being damaged during manufacturing and shipment.

2. Corrosion Resistant Nano Top Coating

A strong corrosion resistance nano coating is manufactured in Japan, considerably enhancing corrosion resistance to acid, alkali, and salt. When harmed on a modest scale, heat activates self-healing.

3. High Gloss Treatment

Increase the gloss of the paint protection film, and keep it glossy.

4. Aliphatic Polyurethane TPU Substrate

This layer possesses high tensile strength, as well as tear resistance, anti-yellowing resistance, aging resistance, and puncture resistance.

5. Ashland Adhesives Layer

Using high-end adhesive from Ashland , there will be no mark guard and no damage to the paint surface.

6. Release Film

It is frequently utilized as the initial barrier between the composite laminate and the rest of the vacuum bagging components, and it is designed to easily manage the laminate's resin content.

| Model | TPU-Ultimate-Black Gloss |

| Material | TPU |

| Thickness | 7.5mil±0.3 |

| Specifications | 1.52*15m |

| Gross Weight | 11kg |

| Net Weight | 9.5kg |

| Package Size | 159*18.5*17.5cm |

| Coating | Nano hydrophobic coating |

| Structure | 2 layers |

| Glue | Ashland |

| Glue Thickness | 23um |

| Film Mounting Type | PET |

| Repair | Automatic thermal repair |

| Puncture Resistance | GB/T1004-2008/>18N |

| UV Barrier | > 98.5% |

| Tensile Strength | > 25mpa |

| Hydrophobic self-cleaning | > +25% |

| Anti-fouling and Corrosion Resistance | > +15% |

| Glare | > +5% |

| Aging Resistance | > +20% |

| Hydrophobic Angle | > 101°-107° |

| Elongation at Break | > 300% |

| Features | Test Method |

| Release Force N/25mm | paste on steel board, 90° 26℃ and 60%, GB2792 |

| Initial Tack N/25mm | under 24℃ and 26%, GB31125-2014 |

| Peel Strength N/25mm | paste on steel board, 180° 15 Minutes under 29℃and 55%, GB/T2792-1998 |

| Holding Power(h) | paste on steel board,hang on by 25mm*25mm*1kg weight under 29℃ and 55%, GB/T4851-1998 |

| Gloss(60°) | GB 8807 |

| Application Temperature | / |

| Service Temperature | / |

| Humidity Resistance | 120 hours exposure |

| Salt-spray Resistance | 120 hours exposure |

| Water Resistance | 120 hours exposure |

| Chemical Resistance | 1hour diesel oil immersion,4hours antifreeze immersion |

| Gloss | >90(%) |

| Aging Test 1 | 7 days under 70°C |

| Aging Test 2 | 10 days under 90°C |

| Tensile Strength | > 25mpa |

| Hydrophobic Self-cleaning | > +25% |

| Anti-fouling and Corrosion Resistance | > +15% |

| Glare | > +5% |

| Aging Resistance | > +20% |

| Hydrophobic Angle | > 101°-107° |

| Elongation at Break | > 300% |

| Self-healing Rate | 35℃ Water 5S 98% |

| Tear Strength | 4700psi |

| Maximum Temperature | 120℃ |

Why choose Boke factory functional film

BOKE's Super Factory boasts independent intellectual property rights and production lines, ensuring full control over product quality and delivery timelines, providing you with stable and reliable smart switchable film solutions. We can customize transmittance, color, size, and shape to meet diverse applications, including commercial buildings, homes, vehicles, and displays. We support brand customization and mass OEM production, fully assisting partners in expanding their market and enhancing their brand value. BOKE is committed to providing efficient and reliable service to our global customers, ensuring on-time delivery and worry-free after-sales service. Contact us today to start your smart switchable film customization journey!

Integration of Advanced Technology and Equipment

To enhance product performance and quality, BOKE continuously invests in research and development, as well as equipment innovation. We have introduced advanced German manufacturing technology, which not only ensures high product performance but also increases production efficiency. In addition, we have brought in high-end equipment from the United States to guarantee that the film's thickness, uniformity, and optical properties meet world-class standards.

Extensive Experience and Independent Innovation

With years of industry experience, BOKE continues to drive product innovation and technological breakthroughs. Our team constantly explores new materials and processes in the R&D field, striving to maintain a technological lead in the market. Through continuous independent innovation, we have improved product performance and optimized production processes, greatly enhancing production efficiency and product consistency.

Precision Production, Strict Quality Control

Our factory is equipped with high-precision production equipment. Through meticulous production management and a strict quality control system, we ensure that every batch of products meets global standards. From raw material selection to every production step, we rigorously monitor every process to ensure the highest quality.

Global Product Supply, Serving the International Market

BOKE Super Factory provides high-quality automotive window film to customers worldwide through a global supply chain network. Our factory boasts strong production capacity, capable of meeting large-volume orders while also supporting customized production to meet the individual needs of diverse customers. We offer fast delivery and global shipping.

contact us

Highly Customization service

BOKE can offer various customization services based on customers' needs. With high-end equipment in the United States, collaboration with German expertise, and strong backing from German raw material suppliers. BOKE's film super factory ALWAYS can meet all of its customers' needs.

Boke can create new film features, colors, and textures to fulfill the specific needs of agents who want to personalize their unique films. Don't hesitate to get in touch with us right away for additional information on customization and pricing.